A typical day at Synnix starts with a positive attitude. And this attitude translates into exceptional service, a “can-do” belief at all levels of our organization, theinception of creative ideas and their development into effective solutions and, of course, a serious manufacturer/developer of outdoor functional woven fabric that is second to none.

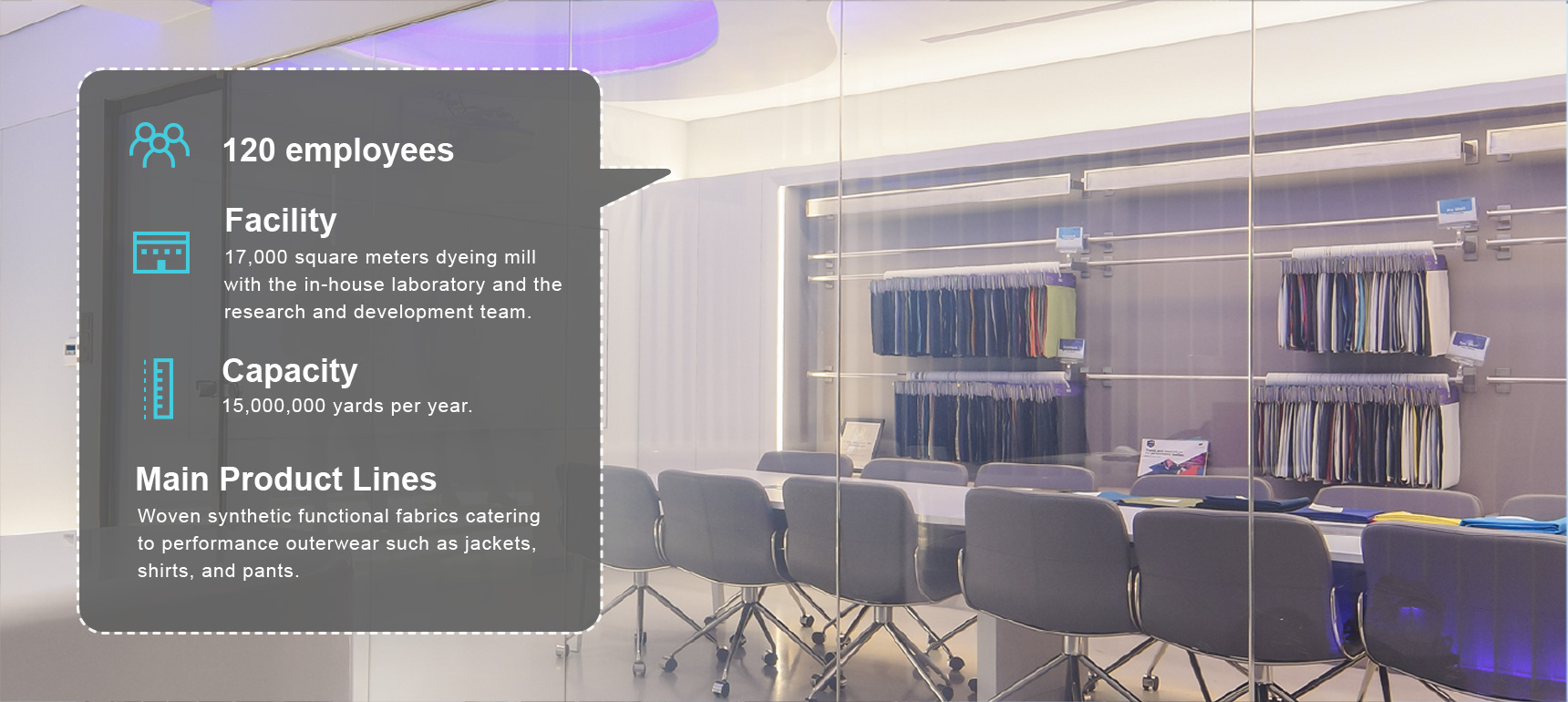

Our confidence stems from having had the pleasure of working with some of the biggest brands in the world in sportswear and outdoor clothing, such as NIKE, Vaude, Columbia, The North Face and many more. Our integrated manufacturing network for innovative fabric, supported by the Synnix Technolog Research Center (STRC), in-house laboratory and dyeing mill are just one of the many reasons our clients choose us.

In addition, we not only care about making a difference in our clients’ lives, but in the world as a whole. That is why we initiated the Synnix Eco-invention task force to help develop processes, technologies and products that contribute to energy conservation. At Synnix, we are fully aware of our green responsibilities as players in the textile industry. And keeping the world green keeps us positive, too.

From spinning, dyeing to coating and laminating, we have established our reputation as a serious player in functional and high performance textile, yet it is the smile on our faces and our great attitude to our job that make us stand out from the rest. Our commitment to bringing expertise with a smile to our clients is what Synnix partners have come to expect. And they are right, we wouldn’t expect anything less.

HISTORY

1993

Guann Lin Textile Co., Ltd. was founded as a trading company and headquartered in Taoyuan, Taiwan.

Guann Lin Group completed and integrated the manufacturing network on the fundamental stage.

2002

Synnix Industries, Inc. was established to complete the renovation of Guann Lin Group facilities, the dyeing mill.

Our own brand, Synnix®, was launched to the global outdoor functional fabric market

2004

The in-house laboratory of Synnix Industries, Inc. for quality assurance was established with the crucial and essential testing machines on functional textiles.

2006

Synnix Industries, Inc. was issued the certification of OEKO-TEX® standard 100 on coated and laminated N/P fabrics with waterproof and breathable finishings.

2007

The in-house laboratory was certificated by L.L. Bean, Adidas, and Nike.

2008

Synnix Technology Research Center (STRC) was established to develop, strengthen, and maintain our top quality assurance systems

The In-house laboratory was certificated by Columbia Sportswear and Vanity Fair.

Synnix Industries, Inc. passed bluesign® screening

2009

Synnix became a bluesign® system partner

2010

Synnix launched a brand new corporate identity ready to take more business opportunities and all future challenges!

2013

ISO9001 training and implementation are currently in progress.

2014

synnix® was issued the certification of ISO9001: 2008 for our main factory and the verification of Recycled PET for our dye and finished woven fabric by Intertek

2016

Synnix acquired Certificate of Compliance issued by Control Union which declares that Synnix has been inspected and assessed according to the Global Recycled Standard (GRS) version 3.0 for Recycled Polyester products.

2017

Contributing to Conserve Resources and Tackle Climate Changes, ISO 50001 is implemented to achieve continual improvement of energy performance, including energy efficiency, energy use and consumption, so as to reduce energy costs and the greenhouse gas emissions.