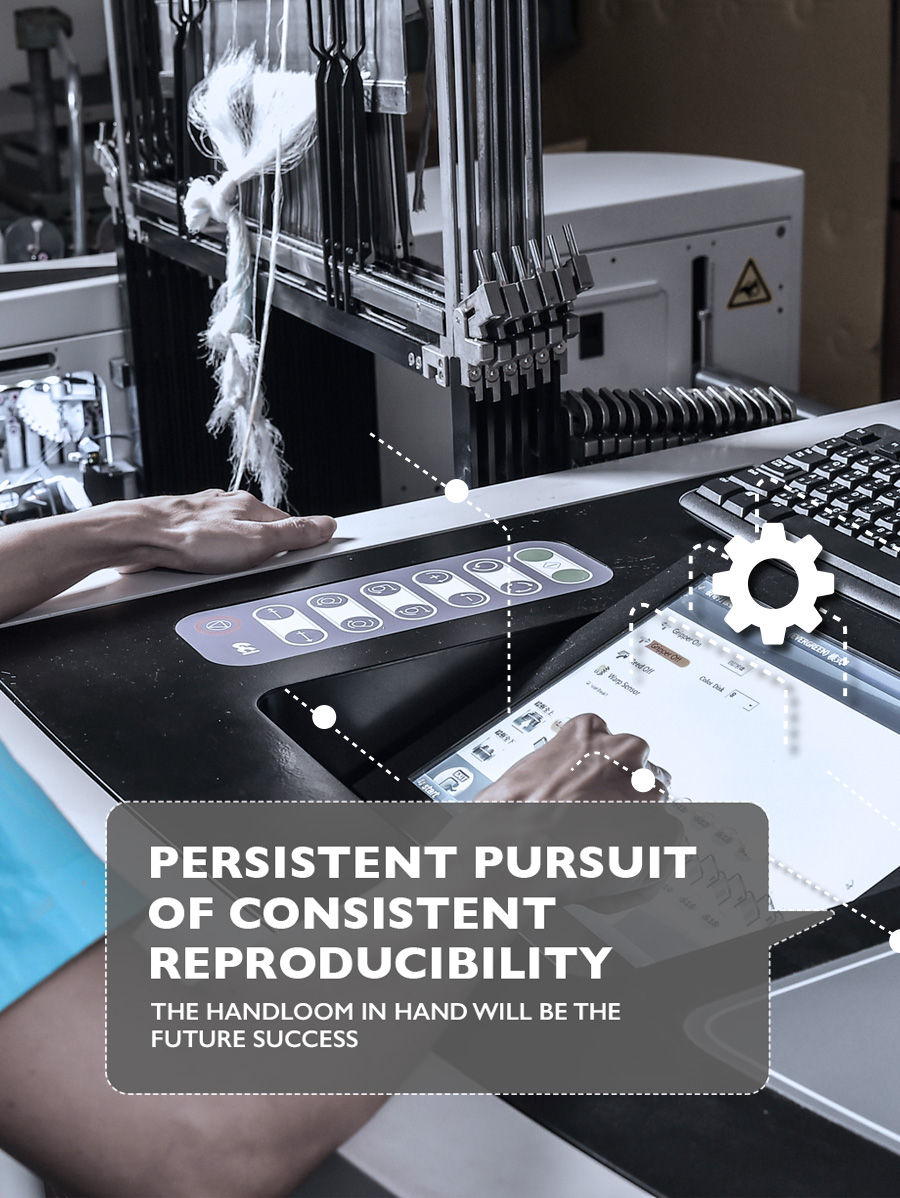

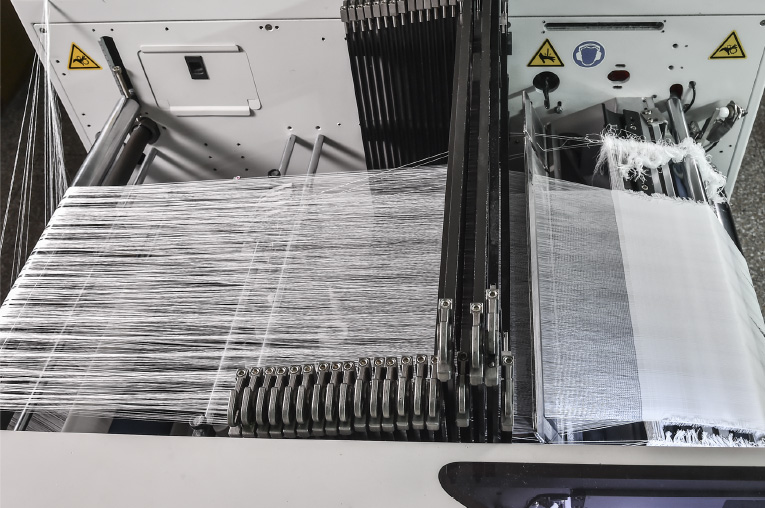

STRC is the soul of synnix® by grasping the most central key of the fabric quality from the four major aspects of appearance, texture, color, and function ; our research and development team continuously collects and observes the latest trends information from different aspects, including material, pattern, and functionality, developing up to approximately 1000 types of fabrics each year. In order to conserve the time and cost of proofing, synnix® is configured with 7 research and development personnel including IMC planning, pattern and textile design, etc…., all performing their own duty delivering the precise fabric samples to the clients. STRC is equipped with a complete handloom machine, which breaks through the existing constraint of sampling period that requires at least two weeks which now is shorten to two days to send handloom for clients to confirm aesthetic and construction of the fabric. Each process of synnix® sample production at STRC from weaving, dyeing, setting, and finishing is recorded as Standard Operating Procedure. Each fabric has its own identification which contributes to the consistency of the finished products’ reproducibility.

“Precise color dipping” is a promise to the clients from all sample and bulk production, maintaining the same standard starting from lab dip to production consistency.

Computer color separation and color matching system: synnix® purchases the latest pantone color standards on request and determines the color recipes combination by the help of spectrophotometer or technician expertise and then connects to the color matching system (automatic titrator) to create color lab dip. The grey cloths will be sent to micro dyeing machine for coloring according to color recipe and sent back for spectro reading to compare the color differences with the standard. The comparison results are automatically marked while lab dip is adjusted repeatedly till matches with the standard precisely.

Three-point control chart: initial assessment (dyeing, drying), in-process assessment (treatment setting i.e. water repellency or wicking), final assessment (finished fabric).

With well-trained color technician and computerized system, considering different color shade alteration due to varied fabric characteristics and finish, the process is divided into three stages. We use three-point control chart to record the spectro reading of the color changing at the end of each stage and adjust repeatedly to ensure the color matching with the standard precisely.

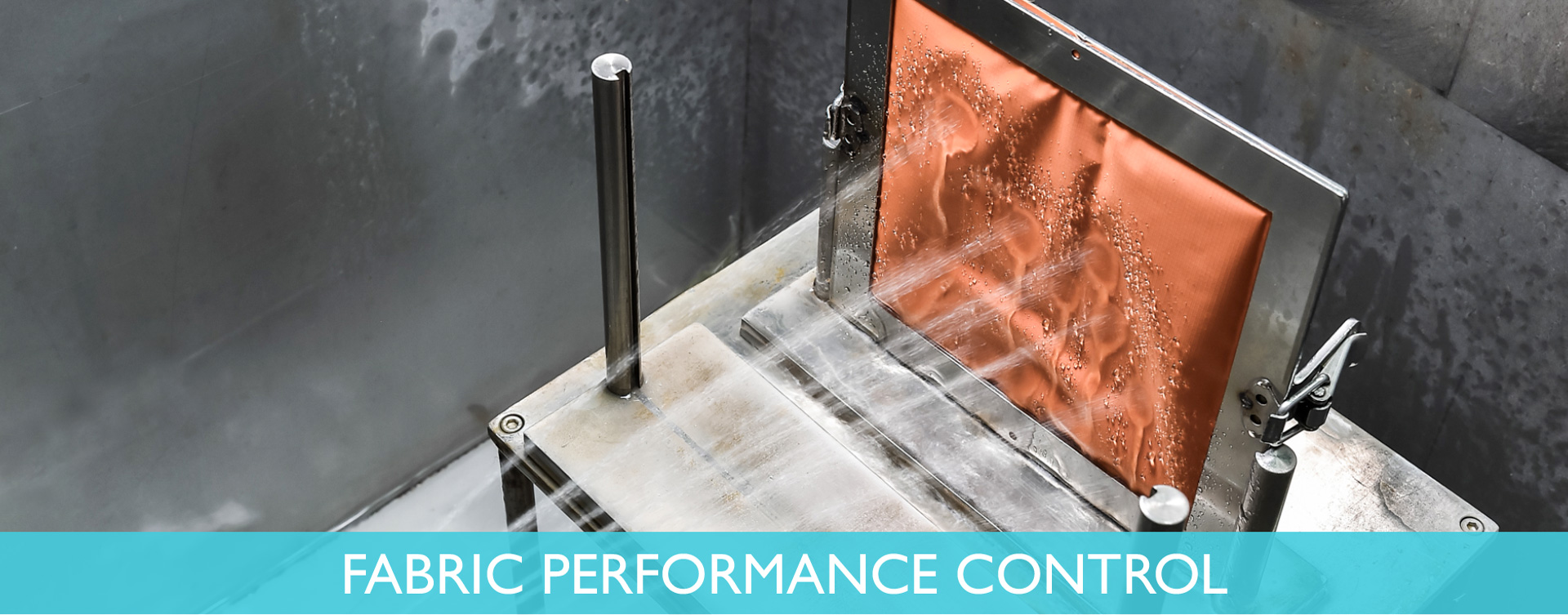

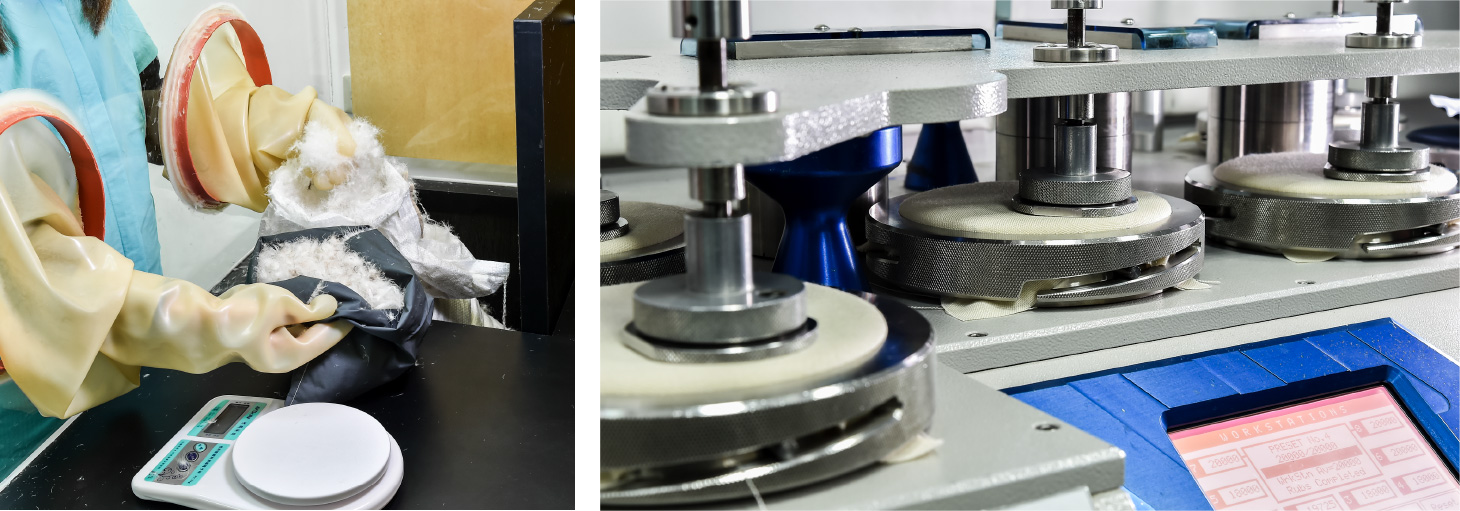

The development of functional fabrics has become more diverse with the goal of creating a more comfortable sports and outdoor wear experience for the consumer. The testing lab of synnix® is built with testing equipment in line with international standards to test various performance, and has obtained relevant certification acknowledged by major brands, ensuring synnix® fabrics meet their expectations. The rare down resistance test is designed especially for the requirements of Nike’s down products, which tests the resistance of fabric to the passage of down and feather under conditions.

Main test items : waterproof, abrasion resistance, tearing strength, snagging, pilling resistance, down resistance, color fastness tests, water repellency, heat shrinkage, wicking and absorbency, air permeability.

Long term stable supply chain management: this is an important part of the front-end process control to minimize waste arose from improper quality control of raw materials from strictly selected and trustworthy suppliers.

Precise sampling: the internal process control emphasizes on the integration between STRC and each division to maintain quality consistency on the four aspects of the finished products including aesthetic, texture, color, and performance to prevent waste of manpower and materials by reducing the debugging time during the back-end process.

Automatic dyeing system : classify by color scheme and arrange the same dyeing sequence to save time on dyestuff changing and tank washing.

synnix® is certified with 9001:2008 international quality management standard, which indicating our determination and efforts on the pursuit of quality. We have established a comprehensive quality control criteria based on the eight major quality management principles:

- Customer focus

- Leadership

- Involvement of people

- Process approach

- System approach to management

- Continual improvement

- Factual approach to decision making

- Mutually beneficial supplier relationships